Topics

Printing in Three Dimensions: How Apparel 3D Printing is Changing the Fashion Game

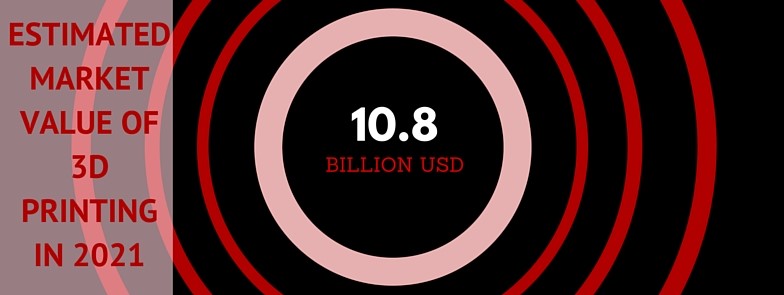

New technology is making 3D printers cheaper and more accessible, affecting the fashion industry in unexpected ways. 3D printed products are becoming increasingly popular, especially among jewelry, clothing and shoe designers. While some critics claim that additive manufacturing technology takes handcrafted work out of the equation, which some designers believe is the quintessence of their garments, many are viewing 3D printed fashion as a new art form. Some fashion brands are eager to produce new and exciting three-dimensional products, leading the way in this never-before-seen process in the fashion world.

How does it work?

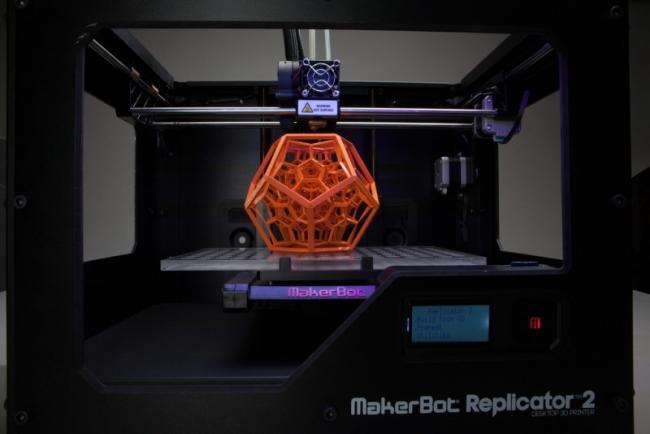

3D Printing creates objects using a CAD file, or computer aided digital file, of the virtual design of an object.[1] If the object is a replica of an already existing object, 3D scanners are used to capture its virtual design. If the object is merely conceptual, a 3D modeling program is used to create the design. The 3D modeling software then splits up the object into hundreds or thousands of horizontal slices, or 2-dimensional images. The printer combines this information to print out each horizontal 2D layer of the object. The layers can be blended together with a variety of techniques, from melting to selective laser sintering (SLS), until the layers are no longer independently visible.

How will it affect the future of fashion?

Andrew Bolton, the curator for this spring’s Met Costume Institute’s exhibition “Manus x Machina,” spoke about how 3D printing will affect the fashion industry in an interview with BloombergPursuits.[2] Bolton revealed that 3D printing will one day be as commonplace as the sewing machine and will be just as groundbreaking. The benefits of 3D printing will be widespread, he believes. Items printed to fit the exact measurements of individual consumers will be common place. This will lead to less production, inventory, and waste, creating a more efficient and ecofriendly manufacturing process. Consumers will no longer have to depend on mass-produced and ill-fitting apparel to remain within the boundaries of their budgets. Bolton predicts that consumers will shift to printing inexpensive and custom-fitted clothing right at home.

Joris Debo is the creative director of Materialise, a Belgian software company noted for their 3D printing technology.[2] She, too, is enthusiastic about the future of apparel 3D printing, though she cautions that the shift will take some time to occur. The current technology is not advanced enough to print garments using truly flexible fabrics. In the meantime, 3D printed objects, such as jewelry, eyewear and footwear, are gaining popularity.

What does 3D fashion look like today?

Wearability

Fashion designer Danit Peleg’s latest collection was created exclusively with 3D printers. Her collection is significant because she overcame one of the largest obstacles designers still have with 3D printers: unwearable textiles[3] Her designs are ready-to-wear and modern, unlike many of the impractical fashion pieces that have been created in the past using 3D printers. Peleg admits that this feat came with a price; her collection took approximately 2,000 hours to print. Peleg relates that two improvements must first be made before 3D printing can become more mainstream: the improvement of printable material and faster printers. If these innovations occur, consumers can expect made-to-order products with low shipping costs, and the option to create their own designs.

What to look forward to

Customization

Kristina Dimitrova, a strong advocate for the integration of fashion and technology, also predicts that fashion designing will be in the hands of consumers.[3] She is the co-founder of Interlaced, an event that connects individuals who are innovating the fashion world with the use of technology. She hopes that the fashion industry will one day be as advanced as other industries, such as the mobile phone industry.

What does this mean for fashion and apparel retailers?

The Fashion Institute of Technology’s Professor Shawn Carter believes that there will be “more consumers designing what they want in partnership with these fast fashion retailers.”[4]

Andrea Bell, WGSN’s Think Tank senior editor, believes that fashion industry will undergo a radical change by allowing consumers a greater say in what goods they are purchasing. She claims that “With 3D printing and things like that, you can, in 10 years, go in and say, ‘I like this bracelet, I’m going to make it and print it out in store.'”[4]

Several brands are finding ways to connect consumers and producers in the design process through 3D printing, not ten years from now, but today. New Balance released the first ever 3D printed running shoe, which features a 3D printed midsole to increase stability, durability, and flexibility.[5] Trove custom jewelry, an online retailer, allows customers to design their own jewelry and select which metal they wish to print it with.[6] Other retailers have followed suit, creating customizable handbags and perfect-fit underwear. We may be entering an entirely new era of fashion and apparel production.

References:

[1] http://3dprinting.com/what-is-3d-printing/

[2] http://www.bloomberg.com/news/articles/2016-04-15/3d-printing-is-poised-...

[3] http://www.sculpteo.com/blog/2015/08/25/danit-peleg-interlaced-electrolo...

[4] https://3dprint.com/111778/3d-printing-fast-fashion/

[5] https://www.thestreet.com/story/13510787/2/here-s-how-3-d-printing-is-tr...

[6] http://www.huffingtonpost.ca/2016/03/10/3d-printing-fashion_n_9431398.html