Daniella Ambrogi is Global Marketing Director for CGS's Application Services division, which offers BlueCherry® software and services to 500+ fashion, footwear, consumer goods and retail companies worldwide. Ambrogi offers 20+ years of experience in the fashion and retail business; she understands a brand's complex needs in an ever-changing marketplace.

Topics

LT Apparel: Building a Bright Future on Strong Foundations

LT Apparel Group (LTAG) has been producing high-quality children’s clothing for more than half a century, through all kinds of unpredictable ups and downs. The company produces children’s apparel for Adidas and Carhartt, as well as its own school uniform company, French Toast.

Even with its considerable history, like everyone else, the company was unprepared for the pandemic and was forced to react quickly. What kept them running was not only their experience, but also their willingness to adapt and invest.

Two years in, as the world continues to look for creative solutions to ongoing supply chain disruptions, companies that want to develop resilience can learn from LTAG. The group successfully leveraged relationships and embraced innovation in the face of difficulty.

‘DO THE RIGHT THING’

The pandemic taught brands and retailers many lessons, including that supply chains cannot run without people. Many factories had to shut down because workers were getting sick. People up and down the supply chain were losing their jobs as many firms canceled orders to cut their losses.

But LTAG decided to base its own moves on longer-term considerations and the appreciation the company has for the people who make its clothes. The company took its own “Do the Right Thing” initiative to heart and continued paying its suppliers—thus protecting the jobs of garment workers.

“We’re long-term players, and we know we can’t succeed without our strategic partners,” Lawrence DeParis, CFO and COO of LTAG, told us in our annual report on supply chain trends and technology.

LTAG’s decision to stick by their suppliers turned out to be prudent. As consumer demand has increased and many businesses are now scrambling to get products on shelves, suppliers have been willing to prioritize production for LTAG. The company invested in building mutual trust with suppliers, and it paid off.

This approach has had value beyond the company’s vendor relationships. LTAG’s holistic consideration of the supply chain aligns with consumer expectations, as well. Recent surveys show that consumers care about the ethics and sustainability of the merchandise they buy, including not only environmental concerns, but also the treatment of manufacturers’ and retailers’ workforces.

The Forbes analysis of a 2021 OpenText survey on consumer preferences suggests that people not only care about ethical sourcing, but also are willing to open their wallets to support it. While 81 percent of respondents said that purchasing ethically sourced products mattered to them, more than 83 percent said they would pay more for these products.

These trends are on the rise. In our recent survey of U.S. consumers and sustainability, 79 percent of respondents ranked sustainable processes as “somewhat important” to “very important” when they shop for new items. That number dipped to 51 percent in 2020, during the heights of the pandemic, but still shows a marked increase over the 68 percent reported in 2019. Additionally, 68 percent of consumers were willing to pay more for sustainably produced fashion and footwear.

By valuing the wellbeing of their suppliers, LTAG built trust with their partners and responded to top consumer demands.

INVEST IN TECH

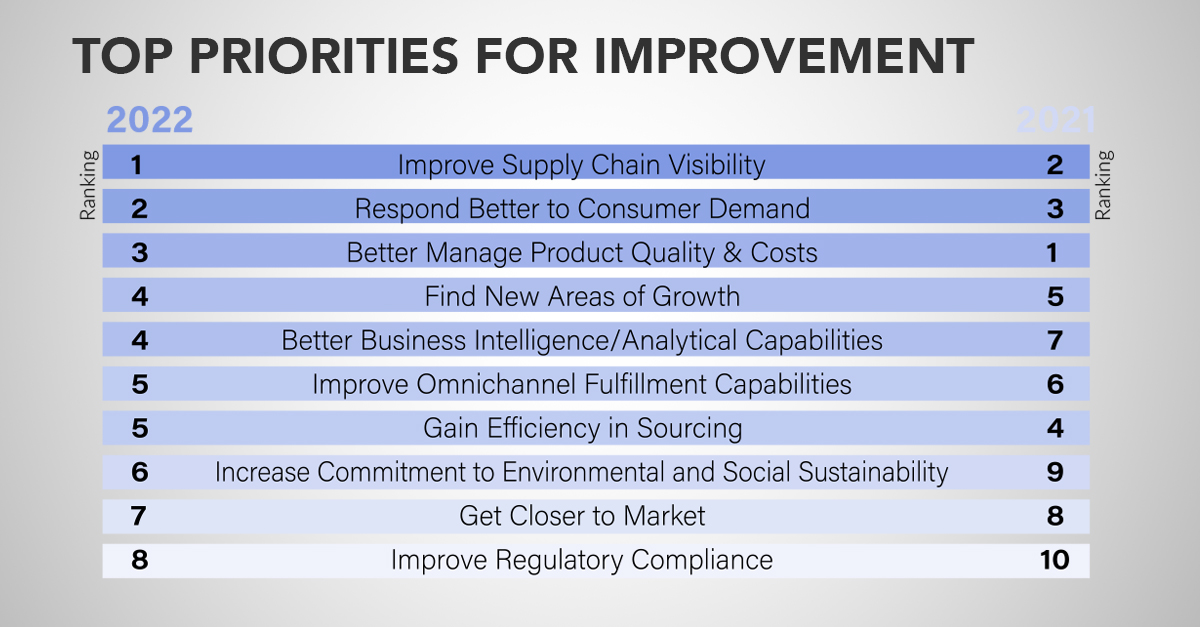

The other key to LTAG’s success in rebounding from the pandemic is its investment in technology. Here, too, the company is fulfilling interconnected missions that are important to most industry players, according to our 2022 annual survey of fashion and consumer product executives. Improving supply chain visibility ranked as their number one priority, followed by responding better to consumer demand.

LTAG’s technology investments have been broad-based. This year, the company is opening a distribution center in Greensboro, N.C., where design, product development, sourcing and merchandising will all happen under the same roof. LTAG has also invested in technology, such as CGS BlueCherry® ERP, which provides them information on where products are in real-time, allowing flexibility and increased efficiency.

“We have to make these investments because it’s more important than ever to harvest efficiencies and embrace digital processes to stay competitive,” DeParis told CGS. “We know that they’ll continue to pay off.”

LEARN MORE

Interested in learning more? LT Apparel’s story is just one of many insights, brand stories and actionable data available in 2022: Fortune Favors the Bold, our latest Supply Chain Trends and Technology report. Get your copy today!

Daniella Ambrogi is Global Marketing Director for CGS's Application Services division, which offers BlueCherry® software and services to 500+ fashion, footwear, consumer goods and retail companies worldwide. Ambrogi offers 20+ years of experience in the fashion and retail business; she understands a brand's complex needs in an ever-changing marketplace.