Topics

PLM Maturity Assessment and Steps to Scale Up

Many retail, apparel and fashion businesses are looking for ways to leverage digital processes to a greater extent. With its ability to streamline communications across teams and supply chain partners, product lifecycle management (PLM) technology often has the potential to be scaled up and used to a much greater extent.

Scaling up PLM need not be an arduous undertaking. There are some straightforward steps any organization can take to simplify, streamline and automate key transactions and tasks with PLM. This post will highlight a few examples. As a result, leaders can strengthen their businesses, make work less stressful for associates and enhance much-needed visibility into end-to-end processes.

What Is the PLM Maturity Curve?

“We implemented PLM years ago. Why would we want to revisit it now?” The answer to this good question is that it’s important to have perspective on where your organization is on the PLM Maturity Curve. Maybe there are new capabilities that didn’t exist during your rollout? Or challenges your staff and supply chain face today that were not an issue before?

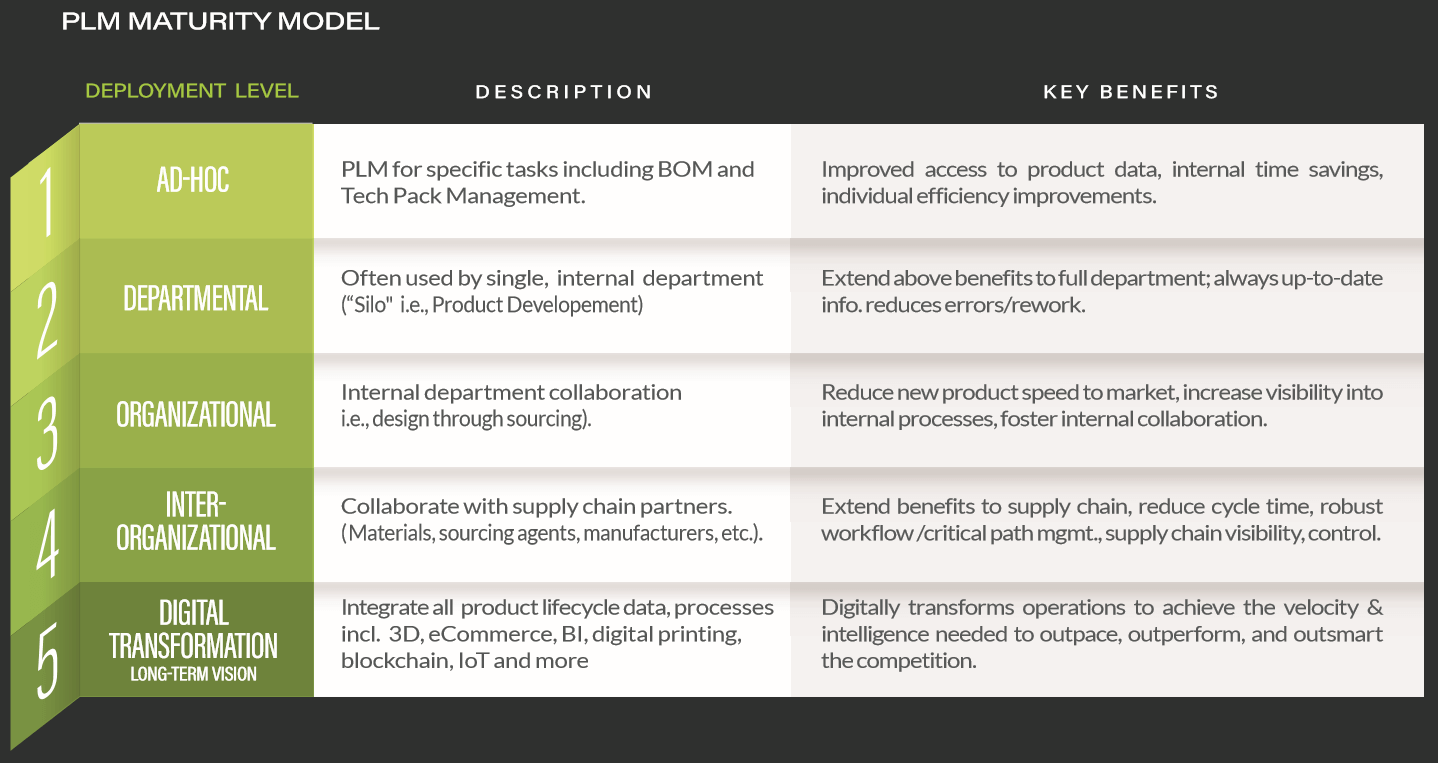

The PLM Maturity Curve is a reference for benchmarking your current PLM utilization and identifying the next steps in your PLM journey. The “curve” refers to the level at which an organization has extended PLM use across different functions and teams, both internally and externally.

The chart below highlights the five stages of maturity levels and reflects how many fashion and retail businesses are using PLM today.

In our 2021 Supply Chain Trends and Technology Report, comparing year-over-year survey results, the share of companies using PLM in a truly integrated way—beyond ad-hoc or single department use—was almost 60 percent. This is a positive, yet modest, uptick of about 5 percentage points. The real story is the significant increase in those leveraging PLM inter-organizationally across their supply chains. This year nearly 20 percent said they achieved this highest level of PLM optimization, up almost 7 percentage points, a 56 percent increase over 2020.

Why and How to Scale Up PLM Now?

Regardless of where you may be on the curve, you can benefit from incremental steps to scale up PLM. Here are some hypothetical examples:

Scaling to Level 2: Ad-hoc to Departmental

- Example: A pattern maker suddenly must go on leave and is unavailable to work on a time-sensitive tech pack that he/she started. The entire product development team has visibility into project status, and a manager can reassign the remaining tech pack tasks to an alternate team member. A co-worker easily picks up where the original pattern maker left off.

- First Step to Scale: Ask your PLM provider about setting up cloud-based access to tech pack data with secure remote access for all approved department members.

Scaling to Level 3: Departmental to Organizational

- Example: The design/product development team has given final approval to a hot style, and it’s time to transition it into production. The sourcing team is in a different city, and many team members are working from home. How can they access the relevant data to start their work? With organization-wide access to PLM, you can seamlessly transfer style details and the bill of materials (BOM) from PLM to ERP, automatically populating purchase orders. Multiple departments have visibility to style and order workflow and are alerted when critical steps need attention. There is no need for phone calls, texting or emailing to keep the job moving.

- First Step to Scale: Ask your solution providers about how you can improve integration between your PLM and ERP systems. If the two are separate systems, consider scheduling an online demo for a solution such as CGS BlueCherry to learn more about what would be involved in migrating to a single, integrated PLM-ERP solution.

Scaling to Level 4: Organizational to Inter-organizational

- Example: The sourcing team needs to quickly move production from one region to another due to factory closures and capacity limits. The COVID-19 pandemic has disrupted the supply chain, and the team needs to pivot its plans. With interorganizational PLM, they can automate the request-for-quote (RFQ) process. Because PLM is integrated with ERP, there is no need to recreate the BOM or send emails with sketches or cost metrics. The RFQ automatically captures this information, and responses can be received within the solution for quick comparison.

- First Step to Scale: Ask your PLM solution provider about setting up a supplier portal or suppliers licenses for exchanging key RFQ data with established and new vendors. Also discuss building direct system integration with your top raw materials suppliers and vendors to enhance real-time supply chain visibility.

Scaling to Level 5: Digital Transformation

- Example: With travel restricted, you need to explore 3D virtual design and sample making and leverage digital printing for faster physical sample production. You want to give customers access to virtual product data they trust, so that they feel confident about placing pre-season orders online without seeing and touching a physical sample. With Level 5 PLM maturity, you replace some physical products and interactions with digital experiences and transactions to keep business moving between your team, suppliers and customers.

- First Step to Scale: Start with one style for your next season and work with your CAD and PLM solution providers to plan a 3D virtual prototyping trial. Talk to your PLM-ERP vendor about feeding style data directly into collaborative B2B eCommerce tools, enabling customers to digitally peruse and buy from your new lines.

Conclusions

Every day, retailers and fashion professionals are facing new challenges to digitize more processes and collaborate globally. The PLM Maturity Curve offers them a quick way to see where they stand with PLM and where they have opportunities to use this powerful technology at another level. By taking steps to scale up PLM within their organizations and eventually their supply chains, they can achieve clearer visibility, better collaboration and greater access to timely, accurate information for decision-making.

Is it time for your business to take that step today to put more robust PLM functionality in the hands of your teams and trading partners?

Download our full guide, “Moving Up the PLM Maturity Curve,” to learn more about maximizing the benefits of PLM within your organization.