Topics

EDI and its Role in Supply Chain Management: Survey Results

The biggest barriers to omnichannel supply chain success for apparel and fashion brands are operational siloes and outdated IT infrastructure. As new technologies emerge and are integrated into Supply Chain Management (SCM) processes, it’s important to continuously evaluate the role and the effectiveness of the entire supply chain system.

EDI (electronic data interchange) is not a brand-new technology, but it remains a key component of many brands’ supply chain management. We conducted a survey of over 100 companies to see how EDI plays a role in their omnichannel supply chain strategies.

The results offer rich insights into how these organizations utilize EDI in order to eliminate operational silos and streamline their supply chain.

Here are a few key takeaways from the survey and what they signify about the current state of EDI in the supply chain.

Who responded?

In terms of company size, respondents were represented quite evenly at all intervals from smaller businesses (<$10 million) to large enterprises (>$1 billion).

Less than $10M 11%

$10M - $25M 8.8%

$25M - $50M 14.3%

$50M - $100M 17.6%

$100M - $150M 6.7%

$150M - $250M 14.3%

$250M - $500 9.9%

$500M - $$1B 7.7%

$1B+ 9.9%

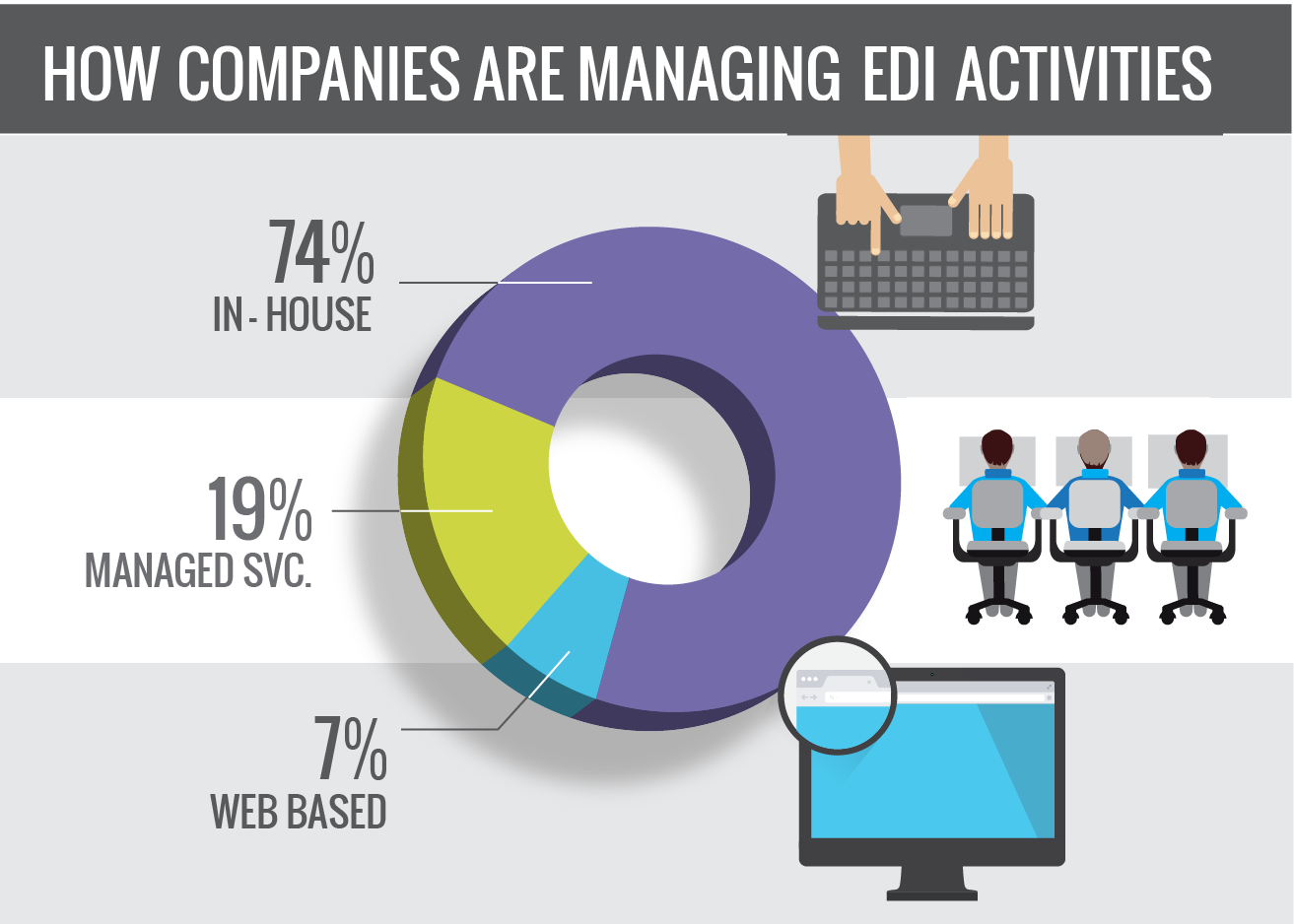

Of the survey’s 114 respondents, the largest group worked within the IT function (32.8% of all respondents). The second-largest segments were in operations and C-level management (both 16.4% of respondents). The rest of the respondents were split between sales (8.6%), product (5.2%), supply chain (5.2%), finance (4.3%) and strategy (2.6%). Most of the respondents were the owners or primary decision-makers for EDI activities in their organization. The majority of the organizations were managing the technology in-house (74%), with 19% using a managed services model and a smaller share of 7% using web-based EDI.

What are the key EDI activities?

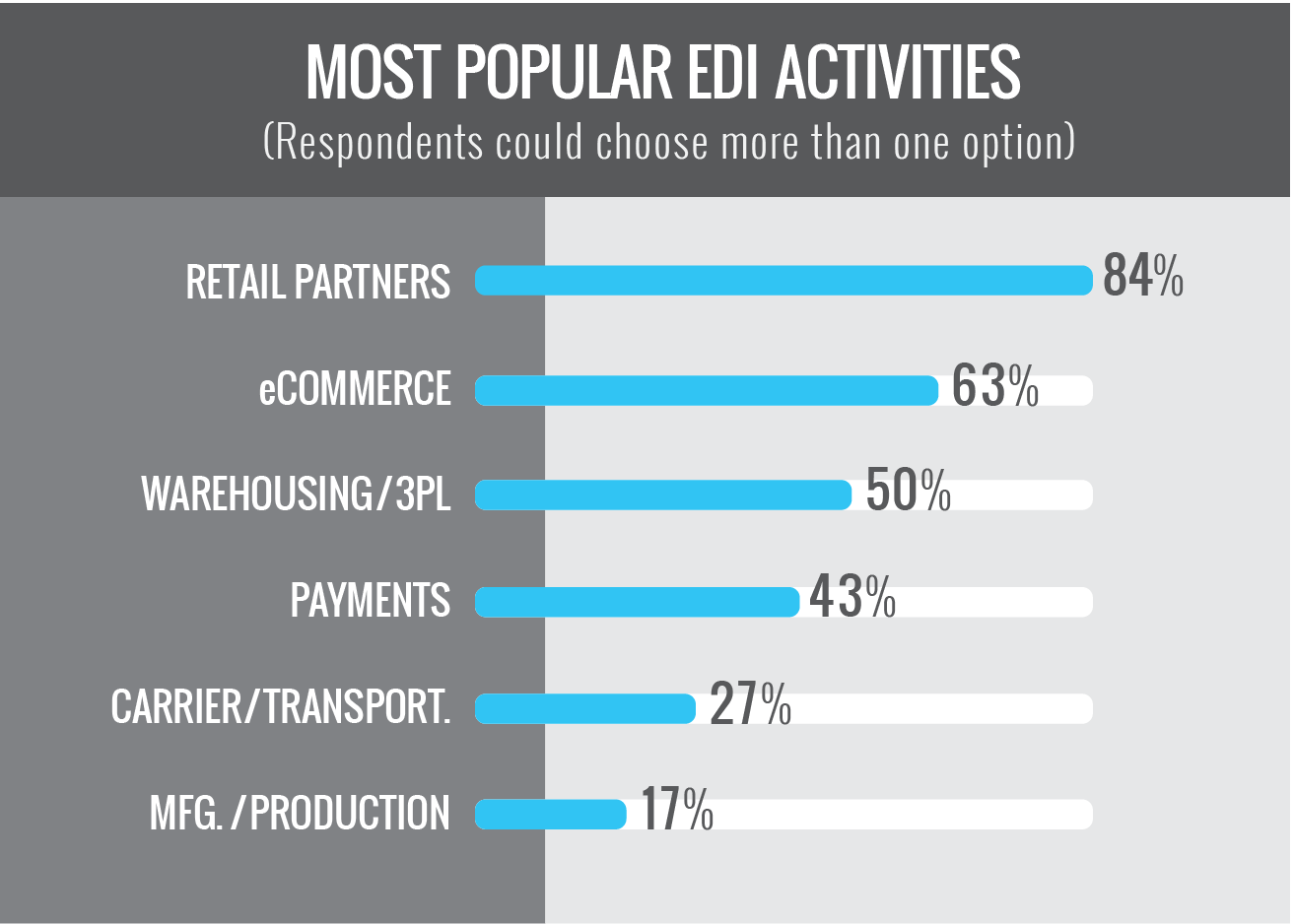

Of the respondents, 75% were using EDI as part of their supply chain management. EDI was used for a range of different activities across the supply chain: Interfacing with retail partners, eCommerce platforms, warehousing or third-party logistics providers, managing relationships with manufacturers, transport or payment providers.

The most popular use for EDI was to interface with retail partners, with 86% of respondents employing it for this purpose. 63% employed it for eCommerce platform integration, and 50% for working with warehousing or 3PL providers. The smallest number of companies used EDI to work with manufacturers (17%). When asked to rank what EDI activities would be most important to their organizations in the future, respondents thought that interacting with retail partners, eCommerce platforms and warehousing / 3PL providers would remain their top priorities.

How important is EDI for omnichannel?

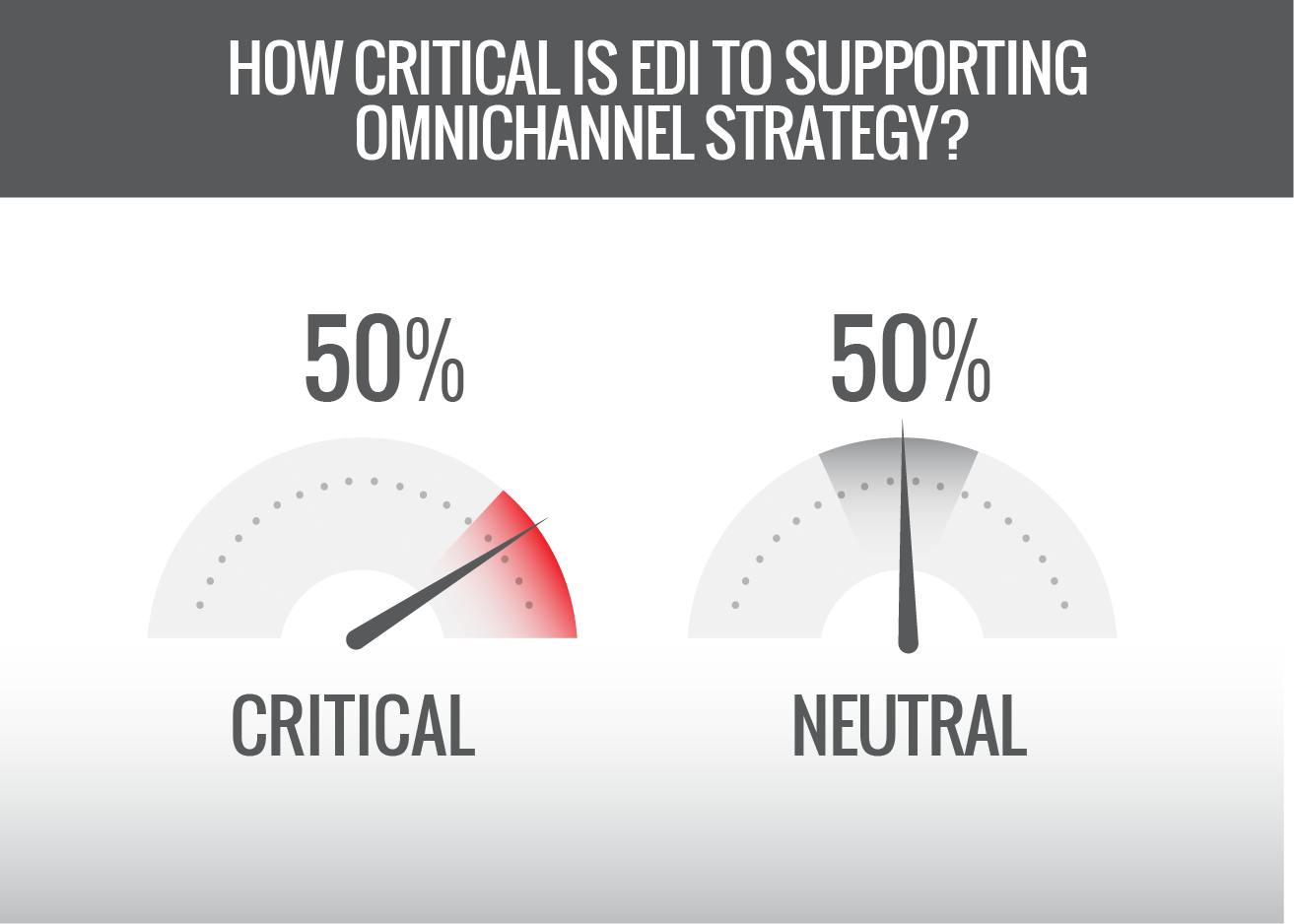

EDI may not be the most buzzed-about component of modern supply chain optimization, but it plays a key role in organizations’ omnichannel strategies. About 50% of all respondents said that EDI was “critical” to supporting their omnichannel strategy and 50% said it was somewhat important.

EDI challenges & priorities

EDI is critical for many respondents, but there are challenges associated with implementing, using and maintaining the technology. We asked an open response question about the biggest challenges organizations had with EDI. The most common responses included:

-Difficulties finding qualified staff to manage EDI systems

-Time, particularly time to get set up with new EDI partners

-Partner requirements, both the lack of standardization between them and the frequency of updates.

-Cost of implementing and maintaining EDI

EDI helps organizations meet a range of objectives for supply chain management. In order, the main priorities organizations have for EDI are:

1: Reducing processing time

2: Improving productivity

3: Reducing errors

4: Reducing chargebacks

5: Improving inventory and warehouse management

6: Streamlining their supply chain

7: Improving trading partner relationships

8: Better managing high volumes of data

As the results of this survey attest, EDI remains a critical component in organizations’ supply chain management strategies. Despite certain challenges, EDI continues to help companies better manage their supply chain processes, reduce operational silos, improve organizational efficiency and reduce errors.

Discover how to enable omnichannel transitions through new systems and workflows