Topics

Key Steps to Guide Your ERP Selection Strategy

Managing Change in the Footwear and Apparel Industry

Technology changes rapidly, but apparel and footwear industry trends change even faster – according to data from IBISWorld, 68,000 new sneakers styles hit the web every three months and men’s clothing is outpacing cameras, computers and other consumer products in growth of online sales.

Consumers want immediate access to the very latest popular styles and continue to demand greater product innovation and quality. Today’s digital consumer requires more product information, shopping and delivery options, with style choices varying greatly from month-to-month.

In a recent report by Gartner titled ‘Top Tech Trends in the Apparel Market’, Gartner stated the case for continued IT investments, with an emphasis on supply chain efficiency, reliability and scalability to deal with oncoming market disruptors and the rapid re-invention of business models in this industry. Gartner found that 46% of apparel professionals do not find their technology portfolios effective for their current business needs. In addition, millennial shoppers and external stakeholders are increasingly questioning the origins of a product and its design and manufacturing processes.

Given this reality and challenges, footwear and apparel businesses need robust technology platforms with expanded capabilities that can easily be configured and updated to address new and changing industry requirements.

You need to be selling product the consumer wants. What the product is and the timeliness of it are the components of what makes or breaks companies. So in our world you have to figure out how to create supply chains to satisfy market needs. And these market needs are always changing – whether millennials, baby boomers or the active grey nomads – what does this mean for product differentiation and distribution strategies?

-Marc Compagnon, president of LF sourcing and director of Li & Fung (Just-Style- Apparel Industry Challenges and Opportunities Report, March 2016)

Enterprise Resource Planning (ERP) systems for manufacturers, wholesalers and retailers in the fashion, footwear and apparel industry must be agile, modern and able to support a huge amount of data, increasingly complex supply chain and production processes and distribution strategies along with providing on-the-go access to essential information from mobile applications and devices.

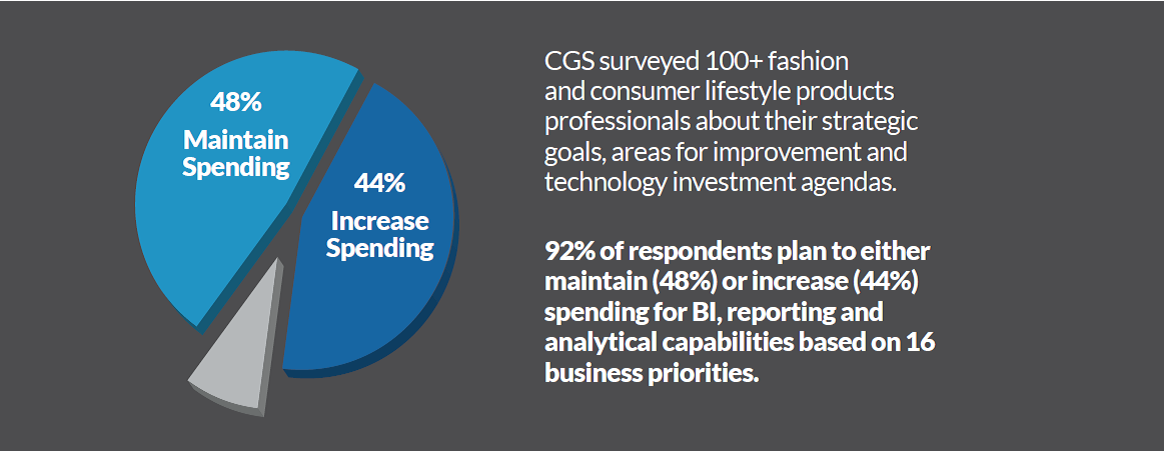

CGS recently conducted a survey of key influencers in the fashion and apparel industry to identify top ERP trends, business issues and challenges. Responses showed the number one priority for business improvement is better reporting and actionable intelligence capabilities.

As hot topics such as big data, analytics and Business Intelligence (BI) cross over into the fashion and apparel world, the real challenge for executives is how to easily, efficiently and proactively gather, analyze and act on all of this smart data including internal, supply chain and customer information.

We believe data is the new oil. The companies that will win are the companies that are using math. As humans we make decisions but it's important we have the best information to make our decisions.

-Kevin Plank, the CEO, chairman and founder of Under Armour

Other technology and apparel trends challenging footwear and apparel industry executives and teams include:

- Pressure for products to comply with all governmental and social regulations, produced under safe working conditions

- Need to adapt to changing business models and distribution strategies such as direct-to-consumer

- Demand for an increasingly agile supply chain capable of developing consistent quality product instantly when and where it is required

- Mastering demanding retail compliance requirements

- The need to control product and operational costs in a highly competitive environment

The Right ERP System Can Combat These Challenges

From production to order management to customer service, ERP is the central nervous system for so many mission-critical functions. Best-in-class ERP software provides advanced integrated reporting and analytics and facilitates collaboration among your in-house business teams and global supply chain operations.

An ERP platform with the latest actionable intelligence capabilities can provide both predictive and prescriptive analytics. In other words, they can cull through huge amounts of historical data and meld it with real-time information, whether from the supply chain or the latest forecasts. From that analysis, these tools can alert executives about brewing problems or potential opportunities, recommend courses of action to help footwear and apparel businesses be more responsive to market trends.

With more predictive capabilities, you can make better decisions on what may happen or what is likely to happen, and then companies tend to make better decisions overall. When you have more predictive insight into what may impact the business both positively and negatively, you can have two to three scenarios to plan around that.

-Sahir Anand, VP, Principal Analyst, EKN Research

A key goal of any modern ERP system should be to automate time-consuming business processes and data entry to provide better operational efficiency that ultimately impacts overall profitability. For example, suppliers face constant pressures to meet demanding compliance requirements set by their retail customers. Many businesses incur some form of chargeback due to a non-compliance event such as an incorrect ASN. This is a recurring problem for suppliers that drives down margins and negatively impacts their scorecard performance. To avoid chargebacks and meet compliance requirements, many businesses have taken advantage of integrated EDI (Electronic Data Interchange) to automate data exchange processes. EDI saves time and money by eliminating huge amounts of error-prone manual data entry. When integrated with ERP, it reduces processing time and ensures the validity of your data on purchase orders, invoices, shipping notices, inventory reports and other time-sensitive business documents.

Best Practices for ERP Selection

Thirty-seven percent of the businesses surveyed by CGS stated their primary goal was to integrate and centralize business processes across their organizations. The first step toward achieving this goal is to look internally.

Your selection process must start with a cross-functional internal team, and include top management involvement and approval. Analyzing and choosing this important system should not be delegated to technology management only. The group should include day-to-day users and assess current business processes that need automation across departments, office locations and functions.

Then, create an extensive list of requirements then reduce the list to critical core components that will have the greatest positive effect on your company’s bottom line when implemented. Prioritize the list by taking the items that each team identified as high priorities for analysis. These create the roadmap to finding new profit opportunities.

Tips for Selecting the Right ERP System

Once you have documentation of your business processes and requirements, look for a system specific to your industry. It must support everything from concept, creation, production, finance and distribution to the latest consumer support capabilities. It’s essential for your software and service provider to know your business. Every industry has its own requirements – from terminology to specific functionality – and a one-size-fits-all ERP will leave you with many gaps and needed customizations. Whether you are in a specialized sector such as footwear or are a well-known apparel manufacturer, ensure your provider has relevant industry experience. Consider the core values of your ERP vendor if you are looking for a true business partner.

Interview and get references from all providers that you are considering.

- Ask how long the vendor has worked with fashion, apparel and footwear companies, and for how many companies

- Explore ERP cloud hosting options

- Consider the vendor’s implementation strategy

- Review how the ERP integrates with other diverse systems, such as website orders and social media feedback

- Determine integrated reporting, analytics and actionable intelligence capabilities

- Request details on the product roadmap

- Explore customer community programs to share strategies and best practices

Work in close collaboration with your software vendor to plan software demonstrations in detail to confirm the software can be configured to support your unique processes and product details. Another critical area to review is training and user adoption. Be realistic about total time needed for training. How does the system provide user support during and after the implementation?

How to Maximize Overall ERP Value

Your ERP system will provide maximum value if you align and prioritize your internal and supply chain requirements before selection.

Conduct a value analysis to make certain the system is a good fit to meet your strategic and operational goals and be sure to integrate your people and processes—not just the data.

Implement or upgrade your ERP based on your business priorities in small steps and not all at once. Prepare your organization, choose your project evaluation team carefully and keep senior management well-informed and involved. Poor user adoption and resistance to change leads to many ERP implementation failures.

Choose a vendor and implementation partner that will be there through the entire process of planning, implementation, integration, training, support and enhancement.

Finally, put together a roadmap that can guide you and keep your team focused throughout the initial implementation and post-implementation. Return to review it periodically and communicate its status throughout your organization on a continuous basis. With these steps in mind, you should have a smooth transition in integrating a new ERP system.

References-

Outlook 2016 - Apparel Industry Challenges and Opportunities -

25 ERP Trends Shaping the Fashion and Apparel Industry -

6 Technology Trends That Will Impact Fashion Industry -

Rajesh Kumar - CTO & Co-founder, Streamoid Technologies -

Drive Customer Engagement With Advanced Analytics -

Major Challenges Facing Fashion Retail Industry Today -

9 Tips for Selecting and Implementing an ERP System -

8 Ways to get the Most Out of Your ERP System -

How To Select Enterprise Software To Maximize Value