Topics

Manufacturing in America: The Real Benefits and the Drawbacks of Reshoring

Senior fellows at the Brookings Institution, Martin Baily and Barry Bosworth, claim that industrial production is on the rise and has been growing for quite some time. This is a result of several developments: improvements in information technologies, robotics and materials science and energy exploitation methods.[1] The increased popularity of U.S. manufacturing will have a tremendous impact on both consumers and producers: read on to find out how manufacturing in the US could help (or hurt) your brand.

The Cons

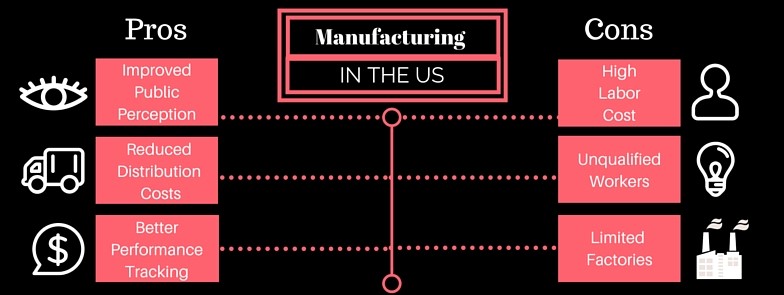

The dispute over increased industrial production in the US has several dividing points. Opponents believe that manufacturing in the US will increase prices, force workers to learn a whole new set of skills and decrease the variety of goods offered [2] Labor costs abroad are significantly cheaper than the cost of labor domestically. When you factor this expense into the cost of production, outsourcing production becomes the logical and more cost-effective option. Outside of the cost difference, manufacturers might still choose to manufacture abroad because many laborers in the US are untrained in the skills necessary to efficiently produce mass quantities of goods. Ample qualified workers can be found in nations that specialize in this type of production, such as Mexico and China. As for factories, their quantity in the United States is limited, and many do not specialize in the wide variety of techniques that is necessary to produce your goods.

Pros

How can US manufacturers overcome the added labor costs of producing goods domestically, which are only worsened by the miniscule amount of skilled laborers in this profession?

If done properly, manufacturing in America can be affordable. This can be achieved with a successful Shop Floor Control (SFC) System,[3] which employs cutting-edge technology. SFC allows for greater visibility over the productivity of plants, which can help reduce production costs. If something is causing an element in the fabrication process to slow, with the right tools, managers can quickly identify the cause and work to eradicate the problem instead of working around the consequences later on. In addition to better performance tracking, domestic retailers will have an improved public perception and brand image.[2] Consumers will appreciate seeing the label “Made in U.S.A.”[2] because it will imply more jobs for Americans and fair labor conditions. SFC will also reduce shipping costs because all of the elements of production- conception, production, and distribution- will be in the same location.[4]

With the rise in technology, production costs have become less problematic. Labor costs, which at one time were detrimental to the budget of manufacturers, are now much lower. Many manufacturing plants are operated by automated machinery. “Robotization” is cheaper than hired workers, incredibly meticulous, and boosts productivity.

International Trade

In the previous section, I discussed why U.S. manufacturing was beneficial for an individual business. On a larger scale, the economy as a whole benefits from increased production of goods in the U.S.

What are the benefits that current international trade has granted consumers? Trade increases competition between producers, decreases prices, and increases the variety of goods and services.[5] The inaccuracy, however, is that an increase in industrial production in the US will not result in an autarky, or a closure to international trade. Instead, the advancements will magnify the effects of international trade.

Let’s think about this from an economics standpoint. Comparative advantage,[3] a concept that dates back to the early 19th century, still stands true and can certainly be applied to this scenario. If Country A can produce a good at a cheaper price than Country B, then Country A will export the good to Country B. Instead of producing the same good at a disadvantage, Country B will produce a good it has an advantage in and export that good to Country A. If the US finds itself capable of producing a good at a cheaper price than the price of an imported good, then it has a comparative advantage in manufacturing the good. If another country has the comparative advantage, then the US should cut its losses and import the good. What does this mean for consumers? Consumers will still have the option to purchase whichever good they prefer, but will now reap the benefits of greater competition: even lower prices and many more options.

Made in U.S.A.

Numerous corporations have found success by producing domestically. Green Toys Inc., an eco-friendly toy company, produces its goods in the United States.[6] The company takes advantage of innovative technology to create toys that are safe for both children and the environment. Green Toys Inc. has experienced an annual growth of 80% since it was established in 2007.[7]

Motorola Mobility, however, did not find as much success producing goods in the US. In 2014, the phone manufacturing company, now under the parent company Lenovo, chose to shut down its Moto X factory in Texas after struggling with sales and manufacturing costs.[8] Neil Mawson, a Strategy Analytics analyst, believes that "The U.S. is well-positioned to design smartphones…but manufacturing them is a whole different ballgame."[8] The company chose to continue manufacturing the Moto X device, but in Brazil, China, and other locations abroad. Maybe Mawson was correct in his claim that the U.S. is not equipped in manufacturing smartphones, but it would be interesting to see how technology such as Shop Floor Control would have impacted Motorola’s production.

References:

[1] http://pubs.aeaweb.org/doi/pdfplus/10.1257/jep.28.1.3

[2] https://www.winddle.com/blog/pros-cons-of-manufacturing-products-in-the-...

[3] https://www.cgsinc.com/en/business-manufacturing-america-guide

[4] http://www.theatlantic.com/business/archive/2014/04/americas-coming-manu...

[5] http://internationalecon.com/Trade/Tch40/T40-0.php

[6] http://www.greentoys.com/our-passion?sec=about-us#about-us

[7] http://www.inc.com/best-industries-2011/green-toys.html

[8] http://www.techtimes.com/articles/7843/20140601/no-longer-made-in-usa-mo...